Custom size PP Woven 1 Ton Jumbo Bags high-capacity FIBC Bag 1000kg Big Bags

Top Option (Filling):Top Fill Skirt

Bottom Option (Discharge):Flat Bottom

Feature:un

Place of Origin:Henan, China

Product name:Big Bag

Material:pp

Size:90*90*110cm /Customized Size

Printing:Acceptable

SF:5:1 / 6:1

Loop Option (Lifting):Four Loops

Safety Factor:5:1

Loading Weight:1000kg

Brand Name: JO EE

Color:white Color

Name:tonne Bag

Logo:Accept Customized Logo

Loop:4 corner Loops

1) Safety:

When you load and transport large amounts of stone, gravel, soil, debris and other various construction materials, it’s important that the bulk container is very durable and extremely safe to use. When used properly, FIBCs are an extremely safe way to transport and store construction materials. FIBCs are manufactured using woven polypropylene creating an incredibly strong and flexible bulk container perfect for most construction applications.

2) Ease of Transport:

FIBCs are flexible in nature (hence the name flexible intermediate bulk container) making transporting them to their end destination easier than other options. Not only is it easy to load full bags onto trucks, they can also have a close-able top to prevent the contents of the bag from falling out and creating hazards during the transportation process.

3) Cost-Effectiveness:

Cutting costs and saving money is a priority of every business. Costs of transporting and disposing of construction materials can be costly and can eat into your already slim margins. Not only are these bags cost-effective, they are extremely lightweight which may help you reduce your overall transportation costs.

4) Efficiency:

You are in the construction business. You know that having the right tools for the job is essential to being able to perform at your highest level. Having the right bulk container for your operations is no different. Properly using bulk bags can make your operation more efficient and effective.

5) Environmentally Conscious:

Some bags are specifically manufactured for multiple uses and are made with a higher safety factor ratio of 6:1. When reusing bags, they should be used in a closed loop system and reconditioned an qualified for reuse by going through the process found here

Are you manufacture?

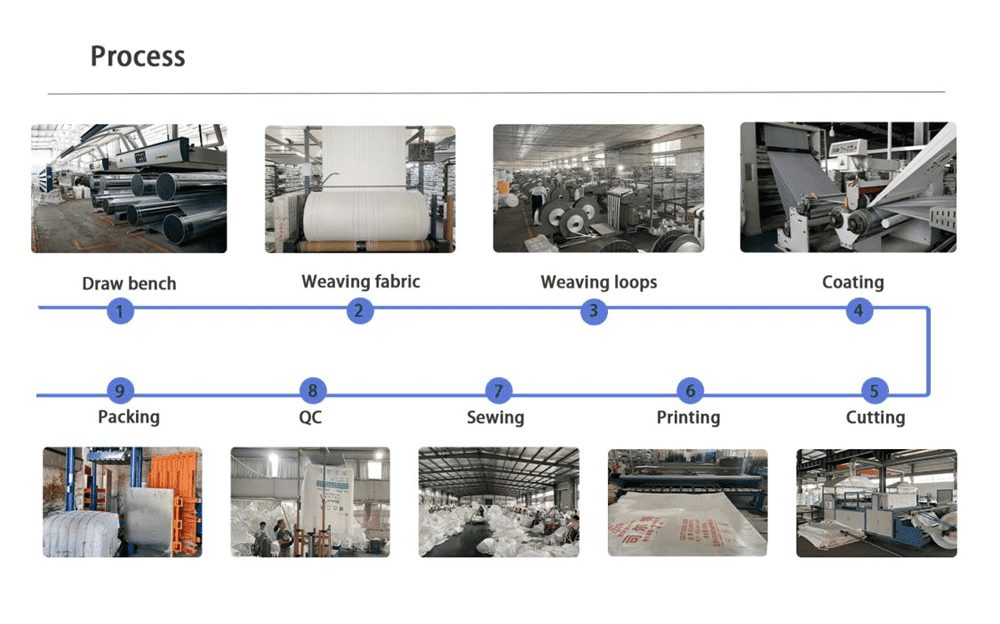

Yes,We are factory name Yanshi Fenghe Packing Materials Co., Ltd(JO EE TRADING Co.,Ltd) located in the beautiful LuoYang City,Henan Province,China.We have professionally manufactured bulk bag, FIBC bag, Jumbo bag and PP woven bag for 13 years.We use high-quality petrochemical polypropylene and polyethylene as raw materials.My company have circular loom 120 units and have 6 production lines with advanced high-speed brushed,PE Coating wire 2 production lines.We have excellent management teams.Professional manufacturing process, stringent production process.We committed to solving various packaging problems for different customers.We warmly welcome your visit for consultation and cooperation.

What is your MOQ ?

Normally MOQ is10,000pcs But we could also make the products for you if your quantity doesn't reach our MOQ,As for we have our minimum volume of business per order. Therefore as long as you pay us the minimum volume of business, even if your quantity less than 10,000pcs, we could also make the bags for you according to your demand.

Can you OEM?

Yes,We can OEM for you,my factory can produce on your Logo for Container Bag Ton Bag sand bag Circular Bag U-panel Bag.

Styles of Bag Construction Bulk bag,jumbo bag,FIBC bag

Circular – This style of bag is made on the loom as a tube and is the lowest standard of FIBC. It will not maintain its shape when loaded and will sit down and bulge out in the middle. It will resemble a tomato when loaded, as the product will stretch the fabric when it is subjected to the pressure of the product being loaded.

U-Panel – A U-panel bag is a step up from a circular bag, as it will have two pieces of fabric resembling a U shape that are sewn together to make the shape of the bag. It will maintain its square shape much better than the circular style.

Four-Panel – The four-panel bag is the best bag for staying square other than a baffle bag. It is made of up four pieces of fabric that make up the sides and one for the bottom. These are all sewn together which resists the stretching tendencies of the bag and holds it in a cube shape much better.

Baffle – This style will be the best at keeping the cube shape of your product when the bag is loaded. It has additional baffles sewn down each corner to act as a pocket to fill each corner. In addition, there are other pockets sewn on each side for all the product to gather around the baffles and pockets. These are perfect if you have a small diameter product such as soybeans which can flow through the baffles without getting hung up. These bulk bags will be easier to stack as they will make a nice square cube.

Specialty bags:

- Pharmaceutical - similar to food grade certifications

- UN certified - will have to undergo many tests to ensure it can withstand the stress and still eliminate spillage of hazardous material

- Food Grade - has to be manufactured in a clean room environment which is BRC or FDA approved

- Ventilated FIBC - used for potatoes and other fruits/vegetables for allowing the product to breathe